to meet the specific needs and tolerances

of your custom stainless steel parts.

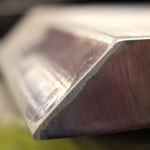

Bevel edge cutting technology with plasma torch machines has improved significantly, and extremely accurate and precise results are achievable. Stainless Plate Products' operators are the best in the business, highly trained with years of experience. From the drawing to shipping we are focused on quality and, when it comes to bevel cuts, our plasma machinists are second-to-none.

Stainless Plate Products' beveling capability saves your project time and money as it is executed in-line as part of the product fabrication process. This kind of efficiency combined with a vast inventory, fast turnaround times and the most experience in the industry makes Stainless Plate Products, Inc. the right choice for your beveled plate product.

Operation

Stainless Plate Products' plasma machines are state-of-the-art and can bevel plate material of varying thicknesses. Thicker gauges are also available depending on the type of bevel required. Our knowledge of plasma beveling technology can determine the final part quality. The SPP plasma system offers the best-quality cuts, higher cutting speed and much reduced overall taper angle when compared to higher-amperage conventional plasma systems.

Beveling a precise machined appearance from a stainless steel plate requires high-end machines and experienced operators. Often bevels will feature a rolled-over edge but SPP operators plan each product fabrication with project managers for most efficient process and the best result. Clean straight bevels, reverseI-cut bevels, I-cuts, negative bevels and K-cuts are all achievable with accuracy and quality at SPP.

Technological advances have allowed plasma torch manufacturers to engineer new models with smaller nozzles and thinner plasma arcs that deliver near-laser precision on plasma cut edges. SPP combines precision CNC control with these torches to fabricate parts that require little or no finishing.

|

|

|

|

|

|

|

| Process | Max. Gauge | Cut Quality |

Cut Tolerance |

Delivery Turn-around |

Heat Affected Zone |

| Machine Cut | Any | ||||

| Nitrogen Plasma | 3" | ||||

| Argon Plasma | 6 1/2" | ||||

| HD Plasma | 6" | ||||

| Water Jet | Any | ||||

| Bevel Cutting | Any |

Depending on the finish dimensions, type, gauge and intended use, there are usually a number of ways to produce any given part or shape. Each method has its advantages and our experienced sales team is ready to help you select the cutting option with the best quality, delivery and overall value for your application.

Unsure which is the best choice for your stainless plate products?

Let SPP help you choose the best method for your parts. Contact us today!