to meet the specific needs and tolerances

of your custom stainless steel parts.

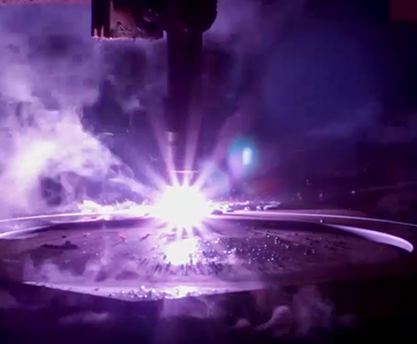

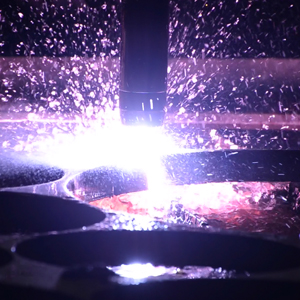

Plasma cutting is a process that SPP uses to cut stainless steel and other metals of different thicknesses using a plasma torch. In this process, an inert gas (in some units, compressed air) is blown at high speed out of a nozzle; at the same time an electrical arc is formed through that gas from the nozzle to the surface being cut, turning some of that gas to plasma. The plasma melts the metal being cut and blows molten metal away from the cut.

Operation

Plasma cutting machines use a high-frequency, high-voltage spark to ionize the air through the torch head and initiate an arc. These do not require the torch to be in contact with the job material when starting, and so are suitable for applications involving computer numerical controlled (CNC) cutting.

Plasma is an effective means of cutting thin and thick materials alike. Hand-held torches can usually cut up to 38mm thick steel plate, and stronger computer-controlled torches can cut steel up to 150 mm thick. Since plasma cutters produce a very hot and very localized "cone" to cut with, they are extremely useful for cutting sheet metal in curved or angled shapes.

Some plasma cutter manufacturers build CNC cutting tables, and some have the cutter built into the table. CNC tables allow a computer to control the torch head producing clean sharp cuts. Modern CNC plasma equipment is capable of multi-axis cutting of thick material, allowing opportunities for complex welding seams that are not possible otherwise. For thinner material, plasma cutting is being progressively replaced by laser cutting, due mainly to the laser cutter's superior hole-cutting abilities.

A specialized use of CNC Plasma Cutters has been in the HVAC industry. Software processes information on ductwork and creates flat patterns to be cut on the cutting table by the plasma torch. This technology has enormously increased productivity within the industry since its introduction in the early 1980s.

In recent years there has been even more development. Traditionally the machines' cutting tables were horizontal, but now vertical CNC plasma cutting machines are available, providing for a smaller footprint, increased flexibility, optimum safety and faster operation.

Technological advances have allowed plasma torch manufacturers to engineer new models with smaller nozzles and thinner plasma arcs that deliver near-laser precision on plasma cut edges. SPP combines precision CNC control with these torches to fabricate parts that require little or no finishing.

High definition plasma cutting is available for parts through 6" thick stainless.

With high definition plasma you can expect:

Improved edge quality and squareness over conventional plasma

Minimal edge bevel

Better quality holes and interior details

Edge quality and cut appearance that approximates laser quality with respect to kerf, edge squareness and smoothness

Little or no dross formation

| Process | Max. Gauge | Cut Quality |

Cut Tolerance |

Delivery Turn-around |

Heat Affected Zone |

| Machine Cut | Any | ||||

| Nitrogen Plasma | 3" | ||||

| Argon Plasma | 6 1/2" | ||||

| HD Plasma | 6" | ||||

| Water Jet | Any | ||||

| Bevel Cut | Any |

Depending on the finish dimensions, type, gauge and intended use, there are usually a number of ways to produce any given part or shape. Each method has its advantages and our experienced sales team is ready to help you select the cutting option with the best quality, delivery and overall value for your application.

![]() Download our Plasma Cutting White Paper

Download our Plasma Cutting White Paper

Unsure which is the best choice for your stainless plate products?

Let SPP help you choose the best method for your parts. Contact us today!